Tensile and universal testing machines

A Schenck uniaxial and torsion testing machine (250kN, 2000Nm, max frequency about 10-20Hz) and two MTS uniaxial tension-compression hydraulic testing machines (25 kN and 100kN, max frequency about10 – 20Hz) are used in material characterization.

Fatigue testing machines

Two Rumul resonance testing machines for high cycle fatigue (20kN and150kN, testing freq. about 100-150Hz ), specially suited for fatigue testing (S-N curves and crack growth).

Possibility to perform tests at high temperatures and in corrosive environment.

Universal bench with hydraulic rams

Test bench with up to 7 hydraulic actuators for full scale testing of components.

Full-scale test bench for customized applications.

Automated modal analysis

An ABB anthropomorphic robotic arm, coupled with a Polytec laser vibrometer, allows 6-DOF vibration measurements for structural dynamic characterization. Excitation can be imposed using several differently sized electrodynamic shakers, which span a frequency range up to 10 kHz.

Optic and SEM microscopies

Characterization of materials by microstructrure (Scanning Electron Microscope, SEM) and durometric analyses.

Charpy impact test

Possibility to perform customized Charpy impact tests for differently-sized specimens to determine the amount of energy absorbed during fracture.

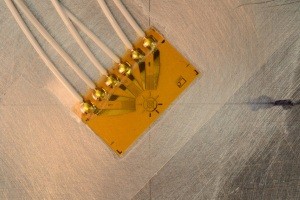

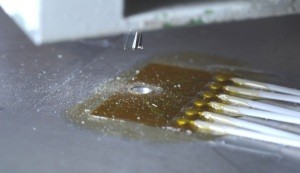

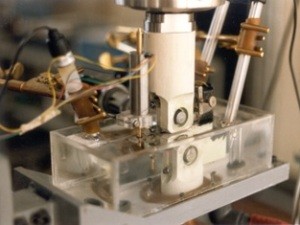

Residual stresses – Hole Drilling Method

Residual stress measurement with the Strain Gage – Hole Drilling Method on metal specimens to characterize any surface treatments such as Shot peening or Deep Rolling.